PRODUCT DESIGN AND DEVELOPMENT Design of Compact, High Temperature Heat Exchangers for Micro-Turbines, Solid Oxide Fuel Cells, and Industrial Heat Recovery

The design and manufacturing of highly effective micro-channel heat exchangers was formerly performed under Zess Industries. A reorganization under MCHX Technology now combines experience systems engineering in power generation, aviation and industrial processes with the pioneering product development and manufacturing experience in high temperature compact heat exchangers.

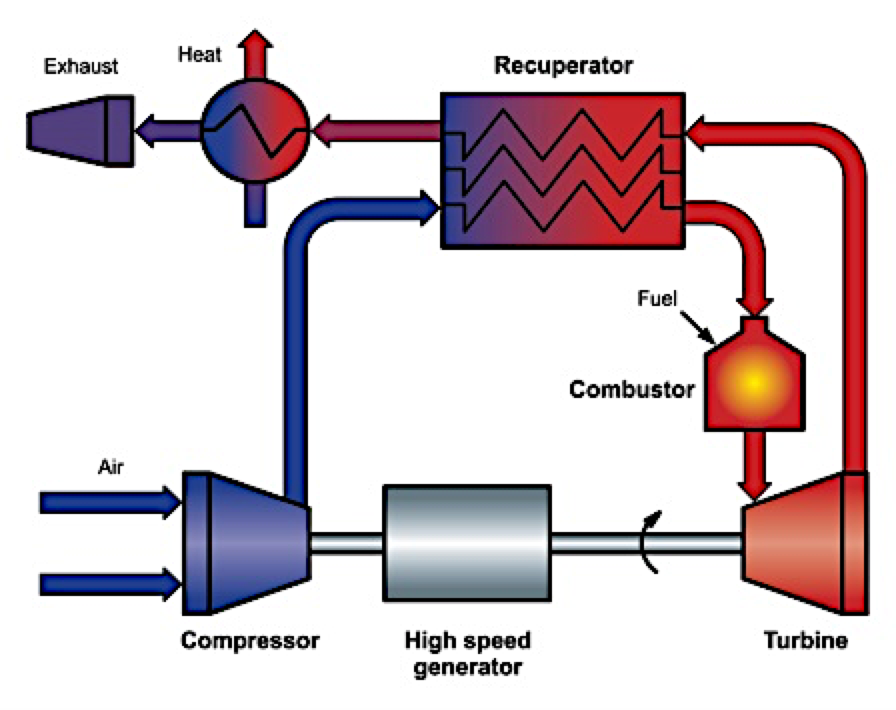

The experienced engineering team at Zess Industries works closely with their customers to design the optimum recuperator for the customer’s system.

High Effectiveness: With counter flow design and high heat transfer coefficients, the MCHX can be designed for an effectiveness exceeding 90%.

Ultra-Compact Size: Exceptionally large heat transfer surface area per volume.

Highly Durable: Made of high temperature metal alloys and designed for long-term, reliable operation without failure in harsh, high temperature environments.

Lighter Weight: For aviation and transportation applications, our heat exchangers are produced of high temperature Titanium alloy qualified for aerospace applications used to reduce recuperator weight.